Why Quality Control Matters

We take the quality and safety of our products very seriously. This is why we have several stops and checks throughout our design, manufacture, shipping and distribution of our products.

The factories in which we produce our products are certified to the highest ISO 9001 standard with additional global safety standards including CE, CB, ETL and more. We also strictly observe the Restriction of Hazardous Substances Acts (RoHS). This means no toxic or other nasty chemicals can contaminate our production lines.

At specific points along each production line the factory has internal quality control checks to maintain standards. Yum Asia then employs a third party independent inspection service that is one of the best in the region to produce a full comprehensive report of each and every production run.

Our factory also makes products for other leading brands such as Cuckoo, Panasonic Tiger and Delonghi so you can be rest assured that you are in good hands.

Approved Countries

Annual Production Runs

Factory Fault Rate

What Do We Check

At a minimum we check the following::

-

1. Electrical Safety Testing1. Electrical Safety Testing

-

2. Components Examination2. Components Examination

-

3. Cooking Profiles Parameter Check3. Cooking Profiles Parameter Check

-

4. Cooking Volume Check4. Cooking Volume Check

-

5. Cooking Results Check5. Cooking Results Check

-

6. Materials, Size And Weight Confirmation

-

7. Stability And Final Approvals

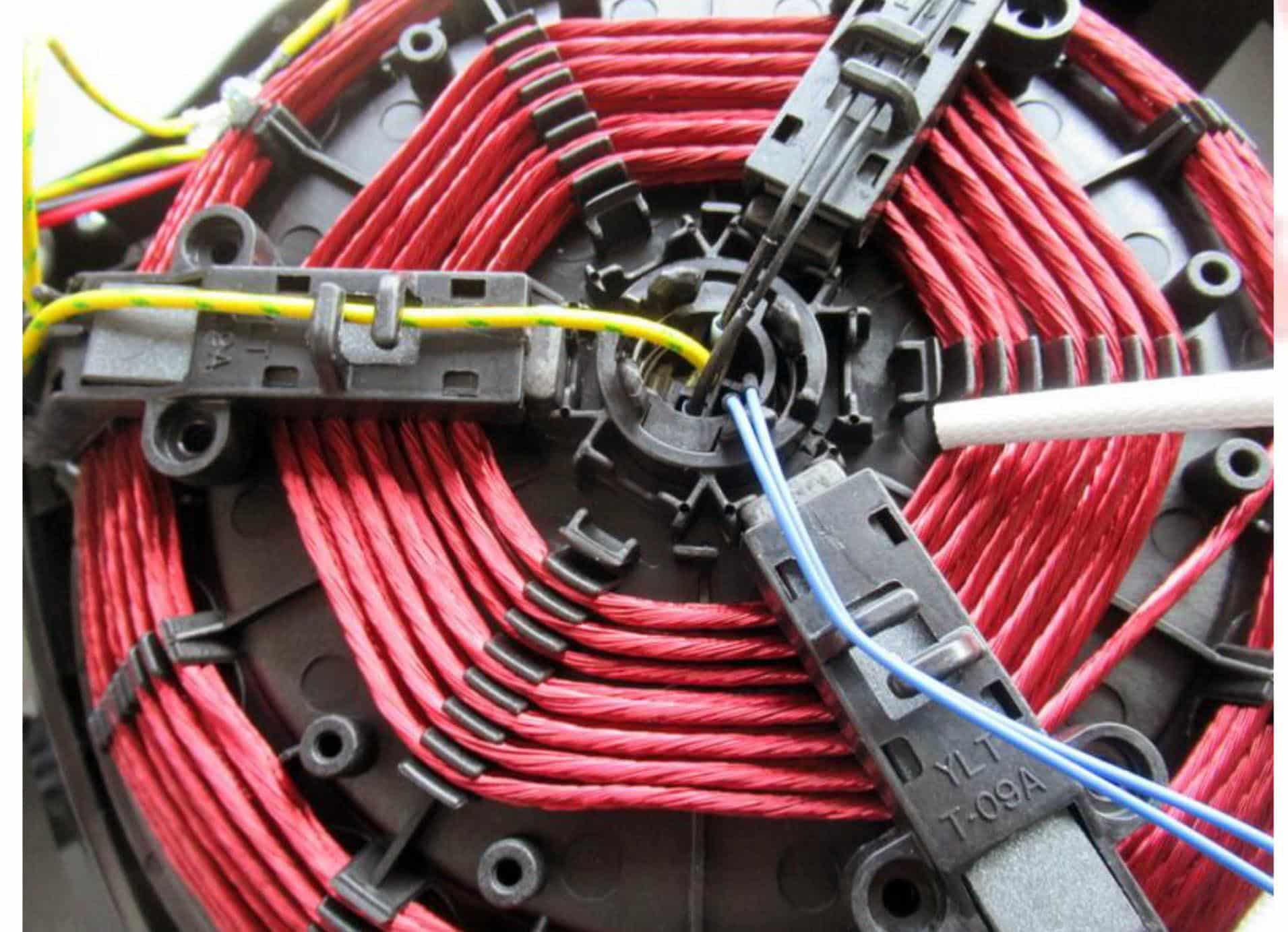

1. Electrical Safety Testing

One of the most important parts of our quality checks concerns the electrics and safety in use of our appliances. In this testing area we examine various aspects including high power loads, power consumption and earth resistance. We check that the power output is correct, that components are correctly protected and all safety standards are observed. Our products don't get any further along the production lines if they fail here.

Energy Use Guidance

2. Components Examination

Every component is tested for reliability (life testing), construction and that they are to the correct standards. This means we use only high quality parts from well established suppliers, Many components are made in-house so we have more control over the component assembly process and helps keep our fault rate down. High quality external suppliers of components are equally essential to us maintaining our high standards.

3. Cooking Profiles Parameter Check

Yum Asia developed cooking profiles which use distinct cooking phases (steam, braise, boil, rest etc) controlled by our own advanced fuzzy logic processing. We check that each cooking phase is working as expected. This includes the temperature range at which food is kept on keep warm (a very important temperature range for food safety).

4. Cooking Volume Check

Our rice cookers have to be able to cook perfect rice with all amounts of rice cooked. This is why we make sure that the rice produced is just as good as when making half a cup of rice up to 8 cups of rice. Yum Asia rice cookers adapt to the weight of the rice, the type of rice being cooked, moisture content, ambient room temperature and other factors.

5. Cooking Results Check

This is probably the most important parts of our development and manufacturing process because we understand how important consistency is with what our cookers make. We do this by performing hundreds of cook cycles at different volumes then test for taste, texture, aroma, rice separation, crusting, hydration, bowl non-stickiness, ceramic material degradation and much more. We look at each programme and put our products through a rigorous testing regime that we call the 'Yum Asia assault course'. Of course we life test the results too to make sure that our cookers perform just as well after 2 years as the day the rice cooker is made.

6. Materials, Size And Weight Confirmation

For every production run every product is tested for exact size, weight and material quality, This includes the inner bowls, gift box, carton boxes, accessories, printing etc. We rigorously check the standard and safety of the final materials which includes thermopolymer appearance, colour, the bowl dimensions, bowl volume, ceramic materials, the stainless steel inner lids, food safe plastic integrity, power plug, power cable length, overall assembly of parts and other final checks.

7. Stability And Final Approvals

The little things count. This is why we check for product stability which includes wobble testing on flat surfaces and making sure lids close and other loose parts are fastened correctly. We perform carton box drop testing to make sure that our packaging protects the products in the way they were designed and reach our customers in perfect condition. We check that every product made is complete and defect free as our most basic level of quality assurance. We perform final checks in our warehouse and distribution hubs. .Only when we are 100% satisifed do they get shipped to customers.

The Yum Asia Quality Assurance Guarantee

Pre Production Testing

The development phase of our products takes many months but sometimes can take several years. In this time we adapt, improve and correct to get perfection. Only then do we move to the next stage.

Safety Certification

Products are passed to the relevant safety standards. This can be CE, CB, ETL. We also ensure hazardous or suspect materials such as PTFE, PFOA, lead, cadmium, BPA etc are not used according to RoHS..

Production QC

During production we have the 7 step quality control plan which is detailed above. This takes place within our factories at various stages of the production lines

Follow Up QA

Every production batch is inspected by a third party for quality. Yum Asia warehousing then is inspected again when factory shipments are globally received.

FREQUENTLY ASKED QUESTIONS

All electrical products sold on this store are made for the South East Asia market. They are 220-240V, 50Hz built and include either a 3 pin or VDE plug and power cable depending on where you purchase. They are all certified to ETL, CE, Malaysian, Singporean and RoHS standards.

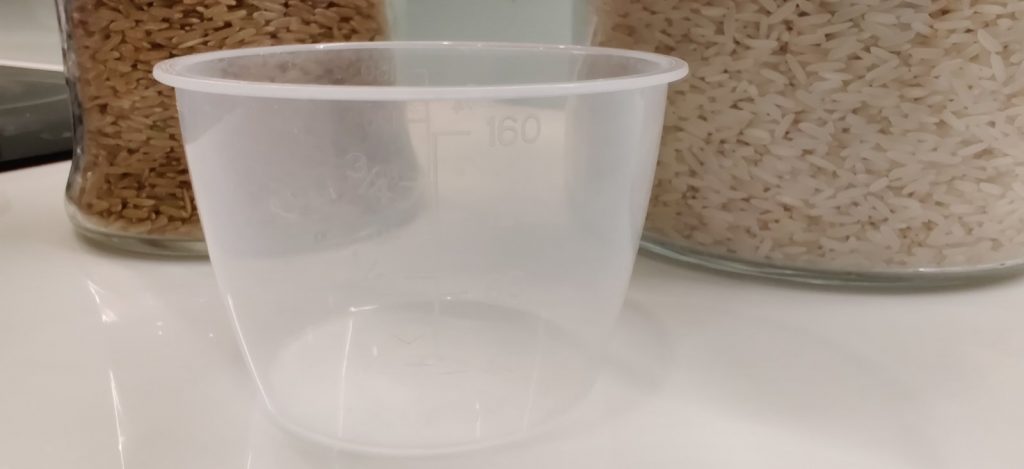

Rice cups are traditionally 180ml (g) but please note that this is to the brim (top) of the rice cup. Whilst the scale of the rice cups goes to 160ml the cup’s capacity is actually 180ml or 180g when fully filled.

So when you fill with rice to get a full 180 mL measuring cup. Don’t forget to go right to the brim and then level off the rice.

You can use the in built Çompare feature of our website’. Every rice cooker has a compare icon you can click. Alternatively you can check our rice cooker comparison page here.

If you are still stuck you can get more guidance from our Choose a rice cooker page here

You can also use our rice cooker advisor tool above. It will ask you a series of questions and then based upon your answers will curate some rice cooker choices for you.

For Yum Asia models in Europe the manual is supplied in English, French, German, Italian and Spanish.

For Yum Asia models in the USA the manual is supplied in English, French and Spanish.

For Zojirushi models the language of the user manuals are English only

Some Chinese-made rice cookers claim to be IH models but they are actually fuzzy logic rice cookers. All fuzzy logic rice cookers have a round metal heating element inside the rice cooker which the inner bowl sits on top of (like a disc with a pressure sensor in the middle). Induction heating models do not have this heating element as they cook by using a magnetic field.

The inside of an Induction Heating model is completely smooth with just a pressure sensor in the middle of the bowl and a pressure line around half way up the side of the inside of the machine to help the magnetic field use the bowl as the heating element. Although the fuzzy logic rice cooker inner bowls are very heavy duty (aluminium coated stainless steel with an outer coating of non-stick), Induction Heating model bowls are much heavier as they are made from different materials (usually aluminium coated stainless steel which is then coated with either copper or a ceramic material as well as a non-stick outer coating) as they need to conduct the heat in a completely different way. It is easy to tell the difference between the two types of rice cooker once you know what you are looking for!

No. For example, UK and European products are not compatible with USA power supply (they are 220-240V and 50Hz) and you would need to purchase a bulky and expensive transformer to convert the voltage so you could use it. Transformers for stepping down voltage take up a lot of electricity when converting voltage, are bulky and don’t convert the cyclical electricity frequency of an appliance (ie they don’t convert from 50Hz to 60Hz). We have had several customers who have tried to use UK?EU rice cookers with a voltage converter and they do not work or broke within 6 months.

Some Asian rice cooker models are confusing also as they are often available in both 110V and 240V power ratings. Please take care if going this route.

Get answers to your questions

Try our help pages or get in touch

We work almost 24 hours, 7 days a week!

Our response usually takes up to 6 hours